May 5th, 2023 - From Crystal Growth to Assembly: The Manufacturing Process of Custom Nal Scintillation Crystals

Scintillation crystals are used in a wide range of applications, from medical imaging to nuclear physics research. Among the most commonly used scintillation materials is sodium iodide (NaI), which is widely used due to its high light yield, good energy resolution, and low cost. In this article, we will provide an overview of the manufacturing process for custom NaI scintillation crystals.

Materials Used

The main materials used in the manufacture of NaI scintillation crystals are sodium iodide (NaI) and thallium (Tl). NaI is a hygroscopic material that can easily absorb moisture from the environment, which can lead to a reduction in scintillation efficiency. Thallium is added to the NaI crystal to improve its scintillation properties. The amount of thallium added can vary depending on the desired scintillation properties of the crystal.

Manufacturing Process

The manufacturing process for NaI scintillation crystals involves several steps, including crystal growth, cutting and polishing, and assembly.

Crystal Growth

The first step in the manufacturing process is to grow the NaI crystal. This is typically done using the Bridgman-Stockbarger method. In this method, a seed crystal of NaI is placed in a high-temperature furnace along with a charge of NaI and Tl. The furnace is heated to a high temperature, causing the NaI and Tl to melt. The seed crystal is then slowly pulled through the molten mixture, allowing a crystal to grow from the seed.

Cutting and Polishing

Once the crystal has been grown, it is cut and polished to the desired size and shape. The cutting and polishing process is typically done using diamond saws and polishing wheels. The crystal is first cut into rough shapes using a diamond saw, and then polished using progressively finer polishing wheels until a smooth surface is achieved. The surface of the crystal is critical to its scintillation properties, as any imperfections can reduce its scintillation efficiency.

Assembly

The final step in the manufacturing process is to assemble the crystal into a scintillation detector. This typically involves mounting the crystal onto a photomultiplier tube (PMT) or other light detector, which converts the light produced by the crystal into an electrical signal. The crystal is typically surrounded by a reflector material, such as aluminum or magnesium oxide, to improve the light collection efficiency.

Technical Specifications

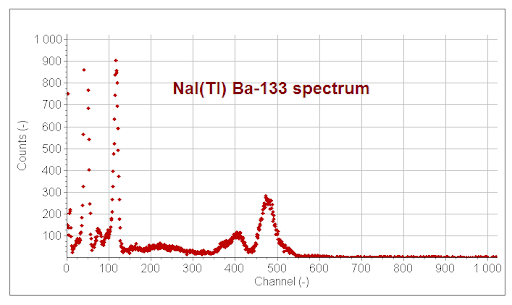

The performance of a NaI scintillation crystal is characterized by several technical specifications, including light output, energy resolution, and decay time. The light output is a measure of the amount of light produced by the crystal per unit of energy deposited. The energy resolution is a measure of the crystal's ability to distinguish between different energy levels of incident radiation. The decay time is a measure of how quickly the crystal's scintillation light output returns to its baseline after being excited by incident radiation.

Berkeley Nucleonics Custom Scintillator

Custom NaI scintillation crystals go through several stages during the manufacturing process, such as crystal growth, cutting and polishing, and assembly. The technical specifications that measure their performance include energy resolution, light output, and decay time. These crystals are well-suited for various applications due to their affordability, high light yield, and excellent energy resolution. If you need a custom NaI scintillation crystal for your project, please fill out the questionnaire linked here.